|

You are here :

Control System Design - Index | Book Contents |

Chapter 1

| Section 1.2

1. The Excitement of Control Engineering

1.2 Motivation for Control Engineering

Feedback control has a long history, which began with the early

desire of humans to harness the materials and forces of nature to

their advantage. Early examples of control devices include

clock-regulating systems and mechanisms for keeping wind-mills

pointed into the wind.

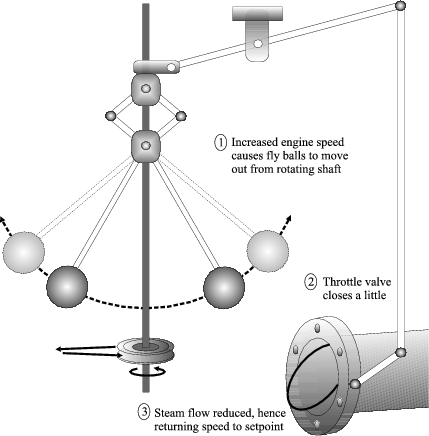

A key step forward in the development of control occurred during

the industrial revolution. At that time, machines were developed

that greatly enhanced the capacity to turn raw materials into

products of benefit to society. The associated machines,

specifically steam engines, involved large amounts of power, and

it was soon realized that this power needed to be

controlled in an organized fashion if the systems were to

operate safely and efficiently. A major development at this time

was Watt's fly-ball governor. This

device regulated the speed of a steam engine by throttling the

flow of steam; see Figure 1.1. These devices

remain in service to this day.

Figure 1.1:

Watt's fly-ball governor

|

The World Wars also led to many developments in control

engineering. Some of these were associated with guidance systems

whilst others were connected with the enhanced manufacturing

requirements necessitated by the war effort.

The push into space in the 1960's and 1970's also depended on

control developments. These developments then flowed back into

consumer goods, as well as into commercial, environmental, and

medical applications. These applications of advanced control have

continued at a rapid pace. To quote just one example from the

author's direct experience, centre-line thickness control in

rolling mills has been a major success story for the application

of advanced control ideas. Indeed, the accuracy of centre-line

thickness control has improved by two orders of magnitude over the

past 50 years, thanks, in part, to enhanced control. For many

companies, these developments were central not merely to increased

profitability but even to remaining in business.

By the end of the twentieth century, control has become a

ubiquitous (but largely unseen) element of modern society.

Virtually every system we come in contact with is underpinned by

sophisticated control systems. Examples range from simple

household products (temperature regulation in air-conditioners,

thermostats in hot-water heaters, etc.), to more sophisticated

systems, such as the family car (which has hundreds of control

loops), to large-scale systems (such as chemical plants, aircraft,

and manufacturing processes). For example, Figure

fig:kellogg shows the process schematic of a Kellogg

ammonia plant. There are about 400

of these plants around the world. An

integrated chemical plant of the type shown in

Figure 1.2 will typically have many hundreds of control

loops. Indeed, for simplicity, we have not shown many of the

utilities in Figure 1.2, yet these also have

substantial numbers of control loops associated with them.

Many of these industrial controllers involve cutting edge

technologies. For example, in the case of rolling mills

(illustrated in Figure 1.3), the control system

involves forces on the order of 2,000 tonnes, speeds up to 120

km/hour, and (in the aluminum industry) tolerances of 5

micrometers or 1/500th of the thickness of a human hair! All of

this is achieved with precision hardware, advanced computational

tools, and sophisticated control algorithms.

Beyond these industrial examples, feedback regulatory

mechanisms are central to the operation of biological systems,

communication networks, national economies, and even human

interactions. Indeed, if one thinks carefully, control in one form

or another can be found in every aspect of life.

In this context, control engineering is concerned with designing,

implementing, and maintaining these systems. As we shall see

later, this is one of the most challenging and interesting areas

of modern engineering. Indeed, to carry out control successfully,

one needs to combine many disciplines, including modeling (to

capture the underlying physics and chemistry of the process),

sensor technology (to measure the status of the system), actuators

(to apply corrective action to the system), communications (to

transmit data), computing (to perform the complex task of changing

measured data into appropriate actuator actions), and interfacing

(to allow the multitude of different components in a control

system to talk to each other in a seamless fashion).

Thus, control engineering is an exciting multidisciplinary subject

with an enormously large range of practical applications.

Moreover, interest in control is unlikely to diminish in the

foreseeable future. On the contrary, it is likely to become ever

more important, because of the increasing globalization of markets

and environmental concerns.

|