|

You are here : Control System Design - Index | Book Contents | Chapter 2 | Section 2.3 2. Introduction to the Principles of Feedback

|

: : |

commanded level of steel in mould |

: : |

actual level of steel in mould |

: : |

valve position |

: : |

casting speed |

: : |

inflow of matter into the mould |

: : |

outflow of matter from the mould. |

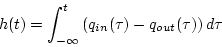

Physics suggests that the mould level will be proportional to the integral of the difference between in- and outflow:

|

(2.3.1) |

where we have assumed a unit cross-section of the mould for

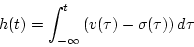

simplicity. We also assume, again for simplicity, that the

measurements of valve position, v(t) and casting speed,

,

are calibrated such that they actually indicate the

corresponding in- and outflows:

,

are calibrated such that they actually indicate the

corresponding in- and outflows:

|

(2.3.2) |

|

(2.3.3) |

Hence, the process model becomes

|

(2.3.4) |

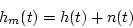

The casting speed can be measured fairly accurately, but mould-level sensors are typically prone to high-frequency measurement noise, which we take into account by introducing an additive spurious signal n(t):

|

(2.3.5) |

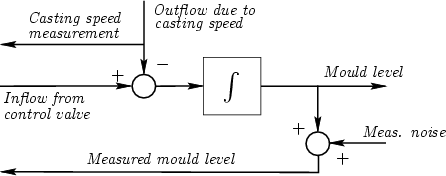

where hm(t) is the measurement of h(t) corrupted by noise. A block diagram of the overall process model and the measurements is shown in Figure 2.3.

This is a very simple model, but it captures the essence of the problem.