|

You are here :

Control System Design - Index | Book Contents |

Chapter 2

| Section 2.3

2. Introduction to the Principles of Feedback

2.3 A Motivating Industrial Example

To make the above general discussion more concrete, we next

present a simplified, yet essentially authentic, example of an

industrial control problem. The example, taken from the steel

industry, is of a particular nature; however, the principal

elements of specifying a desired behavior, modeling and the

necessity for trade-off decisions are generic. Some details of the

example might not be quite clear at this early stage, but they

will set the scene for future work.

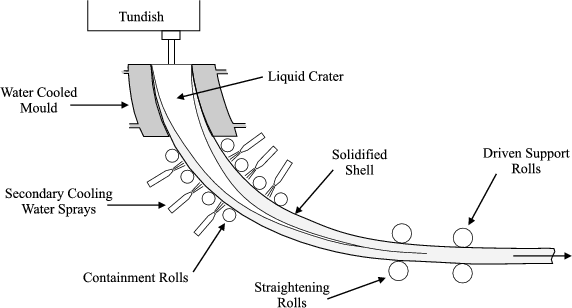

One of the products of the steel industry is a so-called bloom,

which is a rectangular slab of steel. Blooms are produced in a

process called a continuous caster. A diagram of an

industrial bloom caster is given in Figure 2.1. The

principal components of such a system relevant to our discussion

here are shown in Figure 2.2. A photograph of a bloom

caster can be found on the web page.

Figure 2.1:

Process schematic of an industrial bloom caster

|

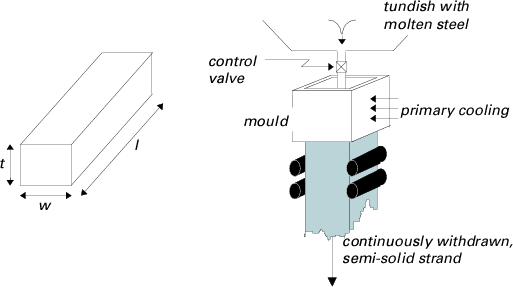

The tundish can be thought of as a large container that

acts as a reservoir for molten steel. A control valve regulates

the rate of flow of steel that enters the mould mounted under the

tundish. The mould, whose cross-sectional area equals the

cross-sectional area of the desired bloom, is open from above and

below. By intense cooling, steel in the mould is cooled to a

semi-solid state. In this state, it is sufficiently firm so that

the strand can be withdrawn continuously from the mould by rolls.

The resulting continuous strand is then subjected to further

cooling and finally cut into blooms.

Figure 2.2:

Continuous caster: typical bloom (left) and simplified diagram (right)

|

Figure W2.1: Photograph of Bloom

Caster.

|