|

You are here :

Control System Design - Index | Book Contents |

Chapter 2

| Section 2.7

2. Introduction to the Principles of Feedback

2.7 From Open- to Closed-Loop Architectures

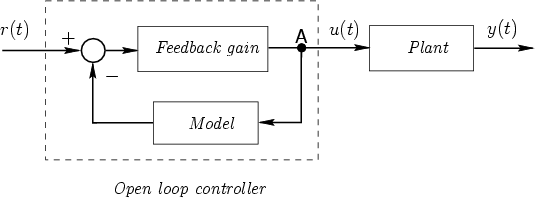

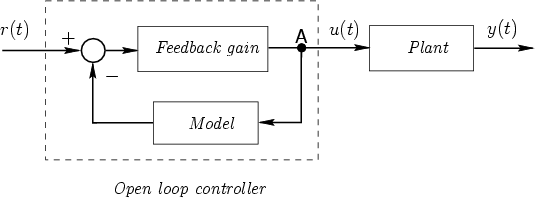

A particular scheme has

been suggested in Figure 2.7 for realizing an

approximate inverse of a plant model. Although the controller in

this scheme is implemented as a feedback system, the control is

actually applied to the plant in open loop. In particular,

we see that the control signal u(t) is independent of what

is actually happening in

the plant. This is a serious drawback, because the

methodology will not lead to a satisfactory solution to the

control problem unless

- the model on which the design of the controller has been based

is a very good representation of the plant,

- the model and its inverse are stable, and

- disturbances and initial conditions are negligible.

We are thus motivated to find an alternative solution to the

problem, one that retains the key features but does not suffer

from the above drawback. This is indeed possible by changing the

scheme slightly so that feedback is placed around the plant

itself rather than around the model.

To develop this idea, we begin with the basic feedback structure

as illustrated in Figure 2.9. We proceed as follows.

Figure 2.9:

Open-loop control with built-in inverse

|

If we assume, for the moment, that the model

in Figure 2.9

is perfect, then we can rearrange the diagram to yield the

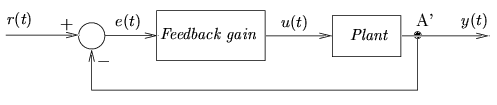

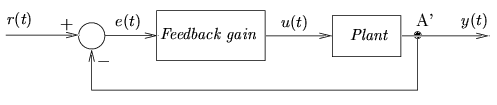

alternative scheme shown in Figure 2.10

Figure 2.10:

Closed-loop control

|

This scheme, which has been derived from an open-loop

architecture, is the basis of feedback

control. The key feature of this scheme is

that the controller output depends not only on the a-priori data

provided by the model but also on what is actually happening at

the plant output at every instant. It has other interesting

features, which are discussed in detail below. However, at this

point, it will be worthwhile to carry out an initial discussion of

the similarities and differences between open- and closed-loop

architectures of the types shown in

Figure 2.9 and

Figure 2.10.

- The first thing to note is that, provided that the model represents

the plant exactly, and that all signals are bounded (i.e., the loop

is stable), then the schemes are equivalent regarding the

relation between r(t) and y(t).

The key

differences are due to disturbances and different initial conditions.

- In the open-loop control scheme the controller incorporates

feedback internally: a signal at point A is fed back. In

closed-loop control, the signal at A' is fed back. The fundamental

difference is that, in the first case, everything happens inside the controller,

either in a computer or in some

external hardware connection. In the second case, the signal

fed back is a process variable: measuring devices are

used to determine what is actually

happening. The heuristic advantages of the latter alternative are

undoubtedly clear to the reader. We will develop the formal

background to these advantages as we proceed.

|